Comparing the engine and the aircraft: A crucial aspect of modern air travel. A critical comparison of the GE90 engine with the Boeing 737 airframe reveals key differences in design, performance, and application.

The GE90 is a high-bypass turbofan engine, renowned for its efficiency and high thrust. The Boeing 737, a family of narrow-body jetliners, is known for its fuel efficiency and versatility in short-to-medium range flights. A direct comparison highlights the intended role of each: the GE90 as a powerful engine driving large aircraft; the 737 as a smaller aircraft powered by various engine types, often including engines that are not the GE90.

The crucial aspect of this comparison is understanding how the engine and aircraft perform in specific contexts. The GE90's design, focusing on lower operating costs per unit of fuel and high thrust for large aircraft, differentiates it from other engines. The 737, adaptable across various configurations, often carries significantly fewer passengers while also maintaining high fuel economy. Historical context matters: the GE90, with its advanced technology, enabled larger-capacity planes. The 737's enduring popularity stems from its adaptability to various routes and passenger needs.

Read also:Best Buffstreams Top Streaming Sites Channels

Understanding these distinct characteristics is essential for appreciating the diverse needs of air travel. The comparison allows informed decisions about choosing between different aircraft types and engines, based on factors such as passenger capacity, range, and operational costs. This knowledge is paramount for airlines, maintenance crews, and aviation enthusiasts alike.

GE90 vs. 737

Understanding the distinctions between the GE90 engine and the Boeing 737 airframe is crucial for comprehending modern aviation. These differences impact performance, efficiency, and application.

- Engine size

- Aircraft size

- Range capacity

- Passenger capacity

- Fuel efficiency

- Cost per seat mile

- Application (long/short haul)

The GE90, a large turbofan engine, is designed for high-thrust, long-range applications. Its size reflects this focus on efficiency for large airliners. The 737, conversely, prioritizes short-to-medium-range flights, offering high passenger capacity and reduced operating costs per seat mile. Engine size directly impacts the size and passenger capacity of the aircraft. Range capacity correlates with the engine's power and the aircraft's fuel tanks. Fuel efficiency is a critical factor in operational costs. A large engine like the GE90, while efficient for very large aircraft, will have a higher cost per seat mile than a smaller engine in a smaller aircraft. The different applicationslong-haul versus short-haul dictate the ideal configuration for the engine and airframe. A comparison highlights these critical considerations in air travel design.

1. Engine size

Engine size is a fundamental factor differentiating the GE90 and the 737. The GE90, a large turbofan engine, is designed for substantial thrust, enabling it to power large aircraft capable of long-range flights. Its size directly correlates with the aircraft's payload capacity and range. Conversely, the 737, a smaller airframe, necessitates a more compact and fuel-efficient engine. This contrasting size directly influences the design and operating characteristics of each platform.

The practical significance of this difference is evident in operational costs. A larger engine like the GE90, while efficient for large aircraft, incurs higher maintenance and fuel consumption costs. A smaller engine, suitable for the 737, leads to lower operational expenses, crucial for short- to medium-range flights. The relationship between engine size and aircraft design also impacts passenger capacity and the overall economics of a flight. In essence, a smaller engine is often necessary for the smaller and more versatile design of the 737 family of aircraft. Real-world examples illustrate this: airlines routinely deploy different engine types within the 737 family based on specific route requirements. This strategic decision highlights the direct link between engine size and the aircraft's ability to meet various operational needs.

In summary, engine size plays a critical role in the performance and cost-effectiveness of the GE90 and the 737. The relationship demonstrates a critical aspect of aircraft design and its impact on long-haul versus short-haul applications. The choice of engine size, directly impacting aircraft design, is a critical consideration for optimizing operational efficiency and meeting specific flight needs.

Read also:Exploring The Intrigues Southern Charm Whitney Gay

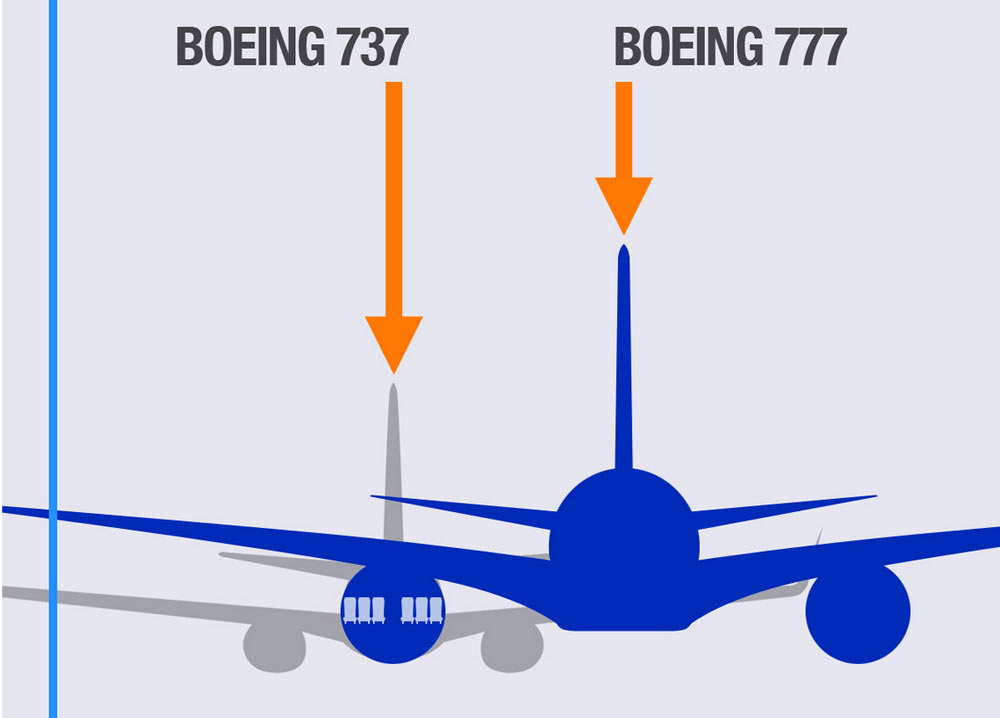

2. Aircraft Size

Aircraft size is intrinsically linked to engine selection. The GE90, a high-thrust engine, is designed for large aircraft capable of long-range flights. Conversely, the 737, a smaller airframe, necessitates a more compact and fuel-efficient engine. This difference in size directly impacts the design, capabilities, and operational costs of each platform. Larger aircraft accommodate more passengers and cargo, but require engines with greater thrust and fuel capacity.

Consider the practical implications. A large airliner, like one powered by GE90 engines, demands a spacious fuselage and substantial fuel reserves to accommodate long-haul flights and substantial passenger loads. This larger size necessitates a more powerful engine to lift the weight. The Boeing 737, designed for shorter hops, accommodates a smaller passenger count and cargo volume, allowing the use of smaller, more fuel-efficient engines. Airlines select aircraft based on their operational needs and routesa long-haul transcontinental flight dictates the use of large aircraft with high-thrust engines. Conversely, a short-haul flight between nearby cities utilizes smaller aircraft and more fuel-efficient engines. Real-world examples demonstrate this principle: airlines frequently utilize different variants of the 737 fleet for varied route lengths and passenger demands. This adaptability showcases the significance of aircraft size in engine selection and operational effectiveness.

Ultimately, understanding the correlation between aircraft size and engine selection is pivotal in aviation. It highlights the diverse needs of air travel, from long-haul journeys requiring high-capacity aircraft and powerful engines to short-haul routes optimizing fuel efficiency. The selection process is a balancing act: maximizing passenger and cargo capacity while maintaining operational efficiency, both economically and in terms of performance. This intimate link emphasizes the critical role of aircraft size in shaping the design and application of aircraft and their engines, directly influencing the economics and efficiency of air travel.

3. Range Capacity

Range capacity is a critical consideration in evaluating the GE90 engine versus the 737 airframe. The distance an aircraft can travel directly correlates with its engine's power and fuel efficiency, influencing operational costs and route suitability. This facet explores the relationship between range and engine/aircraft selection.

- Impact of Engine Power

The GE90's high thrust allows it to power aircraft capable of long-range flights. Its design prioritizes efficiency for extended journeys, crucial for covering significant distances. Conversely, the 737, optimized for shorter routes, features engines designed for lower fuel consumption at lower speeds, impacting range but also maintaining high efficiency for shorter hops. The difference in engine power directly translates to different maximum flight ranges.

- Fuel Efficiency and Design Trade-offs

Fuel efficiency is paramount in determining range capacity. The GE90's design emphasizes high bypass ratios, leading to lower fuel consumption per unit of distance, enabling longer journeys. The 737's smaller engine and aerodynamic design prioritize fuel efficiency for shorter-range operations. These design choices result in different optimal operating ranges.

- Operational Considerations and Route Planning

Range capacity directly impacts operational planning. Airlines choose aircraft and engine combinations based on anticipated route lengths. Routes requiring long distances favor the GE90 and larger aircraft, while shorter routes leverage the 737's range capabilities for cost-effectiveness. Airlines optimize their fleets and route networks accordingly.

- Economic Implications

The range of an aircraft influences its economic viability. Long-range flights, powered by high-thrust engines like the GE90, often generate higher revenue per flight, offsetting higher operating costs per unit of distance. Conversely, short-range flights with the 737, despite lower operating costs per mile, might carry lower revenue if the route is relatively short. Airlines factor these economic implications into their fleet management strategies.

In conclusion, range capacity is a key differentiator between the GE90 and 737, directly influencing design, operating costs, and route planning. The choice of engine and aircraft depends on the specific operational demands, balancing considerations of range, fuel efficiency, and economic viability.

4. Passenger Capacity

Passenger capacity is a pivotal aspect of aircraft design and operational efficiency, particularly when contrasting the GE90 engine with the Boeing 737 airframe. The differing sizes and intended uses of these systems necessitate different approaches to passenger carrying capacity. This exploration examines the multifaceted relationship between passenger capacity, engine type, and aircraft design.

- Impact of Aircraft Size

The fundamental relationship lies in the direct correlation between aircraft size and passenger capacity. Large aircraft, often powered by engines like the GE90, are designed to carry a significantly higher number of passengers compared to the smaller 737. This difference in size fundamentally dictates the design and engineering trade-offs within each system.

- Engine Power and Payload Capacity

Engine power directly affects the payload capacity, a crucial factor for maximum passenger capacity. The higher thrust of the GE90 allows for heavier aircraft capable of carrying more passengers. The 737, using less powerful engines, accommodates a smaller passenger load while emphasizing efficiency for shorter routes.

- Route Considerations and Passenger Demand

Specific operational requirements further influence passenger capacity. The 737 family is commonly deployed on shorter routes, catering to lower passenger demands. On the other hand, routes requiring high passenger capacity, like long-haul international flights, are typically served by larger aircraft powered by GE90 engines.

- Operational Costs and Efficiency

The trade-off between passenger capacity and operational costs is significant. Higher passenger capacities, achieved by larger aircraft, often result in higher fixed costs like maintenance and fuel consumption. Smaller aircraft like the 737, despite carrying fewer passengers, typically have lower operational costs for shorter routes. This cost-benefit analysis is critical for airline profitability.

In conclusion, passenger capacity is a key determinant in the selection of aircraft and engines. The varying needs of different routes and passenger demands dictate whether a large airliner powered by GE90 engines or a smaller, more fuel-efficient model like the 737 is the more suitable choice. Understanding these relationships is crucial for optimizing airline operations and providing the appropriate level of service to meet specific travel needs. This analysis highlights the crucial balance between passenger capacity, engine power, route considerations, and operational costs.

5. Fuel Efficiency

Fuel efficiency is a critical factor in the economic viability and environmental impact of air travel. Comparing the GE90 engine with the Boeing 737 highlights stark differences in fuel consumption patterns, directly impacting operational costs and sustainability. These differences stem from the distinct design philosophies of each system.

- Engine Design and Bypass Ratio

The GE90, designed for large aircraft, features a high-bypass turbofan design. This design prioritizes maximizing the airflow around the engine, reducing friction, and improving overall fuel efficiency during extended flights. The Boeing 737, optimized for shorter routes, incorporates a different bypass ratio and engine design that emphasizes efficient fuel consumption for shorter distances. The smaller engine and streamlined design minimize drag for higher fuel efficiency at lower speeds.

- Aircraft Size and Aerodynamics

The size and aerodynamic design of the aircraft significantly influence fuel consumption. The larger size of the aircraft powered by the GE90 increases the surface area exposed to air resistance, leading to increased fuel consumption. Conversely, the 737's smaller size and optimized aerodynamics reduce drag, enhancing fuel efficiency. The resulting trade-offs in size versus efficiency influence the overall cost-effectiveness of each system.

- Operating Conditions and Flight Profiles

Different flight profiles affect fuel consumption. Long-haul flights, served by GE90-powered aircraft, require sustained high-speed operation, necessitating greater engine output and increased fuel consumption. The shorter flight profiles common with the 737 allow for optimized fuel efficiency, enabling more economic routes. The selection of engine and aircraft considers the expected flight duration and passenger demand.

- Impact on Operational Costs

Fuel efficiency directly impacts operational costs. Lower fuel consumption translates to reduced operating expenses for airlines. The GE90, despite potentially higher fuel consumption per unit of distance in certain conditions, may provide lower operating costs per passenger mile for larger aircraft and longer routes due to economies of scale. The 737, with its efficiency in shorter routes, significantly minimizes fuel consumption costs for those flights. This cost-benefit analysis plays a significant role in airline fleet optimization decisions.

In conclusion, the fuel efficiency comparison between the GE90 and the 737 underscores the trade-offs inherent in aircraft design. The GE90's design prioritizes efficiency for long-haul flights, while the 737's focus is on fuel efficiency for shorter routes. Airlines make strategic decisions based on expected routes, passenger demand, and operational costs. Understanding these intricacies is crucial for assessing the environmental and economic impact of each choice in the context of modern air travel.

6. Cost per Seat Mile

Cost per seat mile (CPM) is a critical metric in aviation, reflecting the cost of transporting a single passenger one mile. Comparing the GE90 engine with the Boeing 737 necessitates examining CPM differences, as it underscores the economic trade-offs inherent in choosing aircraft and engine configurations. Analyzing CPM reveals factors impacting airline profitability and route feasibility.

- Impact of Engine Size and Efficiency

The GE90, with its high thrust and efficiency for large aircraft, typically yields lower CPM on long-haul routes. Its design optimizes fuel consumption per unit of distance for large aircraft, translating to a lower cost per seat mile. The 737, optimized for shorter distances, achieves lower CPM on routes requiring less range, utilizing smaller and more fuel-efficient engines. These differences directly result from the design choices focused on different operational parameters.

- Aircraft Size and Passenger Capacity

Aircraft size plays a vital role in CPM. Larger aircraft, often employing GE90 engines, distribute fixed costs (like maintenance and crew salaries) over a greater passenger capacity, potentially leading to lower CPM on high-capacity routes. Smaller aircraft like the 737, despite lower fixed costs per seat, may have higher CPM on routes with smaller loads. This is crucial for airlines to evaluate which routes are suitable for specific aircraft types.

- Route Length and Passenger Demand

Route length and passenger demand are integral to CPM. Long-haul routes typically see economies of scale, leading to lower CPM for the GE90-powered aircraft, while short-haul routes frequently favor the 737 for its lower CPM. High-demand routes, regardless of length, may favor a larger aircraft even if the CPM is higher, prioritizing greater capacity.

- Operating Costs and Maintenance

Maintenance and operating costs for the different systems vary. GE90 engines, being large and powerful, have higher maintenance costs. The 737, with its smaller engines, typically incurs lower maintenance costs. The larger, more complex nature of a GE90 necessitates more substantial maintenance efforts and greater operating costs. However, the GE90 may offset these costs due to the increased passenger capacity. These costs significantly influence CPM.

In conclusion, understanding the interplay of engine size, aircraft size, route characteristics, and operating costs is essential for accurately evaluating CPM. Airlines employing the GE90 aim to optimize CPM on long-haul routes with high passenger demand, while the 737 family maximizes CPM efficiency on shorter routes, accounting for various factors. The decision between these options becomes a strategic calculation that weighs these factors for maximum profitability.

7. Application (long/short haul)

The application of an aircraft, categorized as long-haul or short-haul, is a defining factor in selecting between engines like the GE90 and the Boeing 737 family. This choice is driven by the inherent trade-offs between range, efficiency, and cost-effectiveness. The optimal selection for a particular route depends on maximizing profitability and suitability for the specific needs of the passengers and the airline.

Long-haul routes, spanning significant distances, necessitate aircraft capable of extended flight times and carrying substantial fuel loads. The GE90 engine, with its high thrust and efficiency for large aircraft, becomes a prime choice. Its design prioritizes maximizing fuel efficiency over shorter distances, making it more economical for long-distance travel, even with the higher maintenance costs. Conversely, short-haul routes demand aircraft optimized for fuel efficiency at lower speeds and shorter flight times. The Boeing 737 family, with its smaller size and more fuel-efficient engines, excels in this scenario. This design choice leads to lower operating costs per passenger mile on shorter routes. Real-world examples illustrate this principle: airlines often deploy different 737 variants for various routes, each tailored to specific passenger volume and flight distance. Similarly, long-haul routes are typically served by aircraft equipped with powerful engines like the GE90.

Understanding this connection is crucial for airline strategists. Fleet management decisions hinge on effectively matching aircraft types to specific routes. Incorrect matching can lead to significant losses due to inefficient fuel consumption or underutilized passenger capacity. Airlines analyze historical data, current passenger demand, and projected fuel costs to make informed decisions. The strategic deployment of aircraft tailored to specific route requirements, considering factors like passenger capacity, range, and operational costs, significantly impacts an airline's financial success. This understanding extends beyond simply choosing an engine; it encompasses the entire operational framework and strategic considerations for route optimization.

Frequently Asked Questions

This section addresses common inquiries regarding the GE90 engine and the Boeing 737 aircraft, providing concise and informative answers.

Question 1: What are the key differences between the GE90 engine and the Boeing 737 aircraft?

The GE90 is a high-bypass turbofan engine, designed primarily for large aircraft needing significant thrust for long-range flights. The Boeing 737 family, a series of narrow-body jetliners, is optimized for shorter routes, accommodating a lower passenger load and emphasizing fuel efficiency. Engine size, aircraft size, and intended application (long-haul vs. short-haul) are key differentiating factors.

Question 2: Which engine is more fuel-efficient?

Fuel efficiency varies based on the specific application. The GE90, due to its high-bypass design and large size, achieves higher fuel efficiency per unit distance for long-haul flights. The Boeing 737, with its more compact design and focus on shorter routes, generally offers better fuel efficiency per seat-mile on shorter journeys.

Question 3: What factors influence the cost per seat mile (CPM) of each?

CPM is influenced by a multitude of factors, including engine size, aircraft size, operating costs, and route length. Large aircraft, like those powered by GE90 engines, typically distribute fixed costs over a greater passenger capacity, leading to lower CPM on high-capacity routes. Conversely, smaller aircraft, such as the 737, generally exhibit lower CPM on shorter routes due to reduced operating costs per seat.

Question 4: Which aircraft type is better for long-haul flights?

The GE90-powered aircraft are generally favored for long-haul flights due to their capacity for extended range and high-thrust capability. These characteristics enable the aircraft to travel significant distances efficiently and comfortably.

Question 5: How do these choices impact airline profitability?

Airline profitability is contingent upon matching aircraft type and engine to appropriate routes. Mismatched selections can lead to operational inefficiencies and decreased profitability. Strategically selecting the most suitable aircraft for specific routes maximizes revenue potential and minimizes operational costs. The CPM of the chosen aircraft is a vital consideration in the decision-making process.

Understanding these distinctions is key to comprehending the advantages and trade-offs associated with different aircraft and engine choices in the commercial aviation sector.

Next, we'll delve into the specifics of engine maintenance and repair procedures.

Conclusion

The comparison of the GE90 engine and the Boeing 737 airframe reveals a complex interplay of factors impacting operational efficiency and profitability. Key distinctions lie in engine size and power, impacting range capacity and passenger capacity. Fuel efficiency, a critical element in operational costs, differs significantly based on the intended application, emphasizing trade-offs between long-haul and short-haul routes. Cost per seat mile (CPM) analysis further underscores the crucial link between aircraft characteristics and route suitability. The choice between these systems ultimately hinges on maximizing profitability by matching the aircraft and engine to the specific demands of the intended route, balancing passenger capacity, range requirements, and operating costs.

This analysis highlights the nuanced decision-making process inherent in aviation. Future developments in engine technology and aircraft design will likely continue to refine these trade-offs. Continued optimization of fuel efficiency and cost reduction strategies will remain paramount for airlines to remain competitive. A deep understanding of these factors is essential for informed decision-making in the aviation industry, optimizing fleet management and maximizing return on investment.

Article Recommendations